TATA

MINING TRUCK WHEEL

WASH SYSTEM

HomeTATA Mining Truck Wheel Wash System

Tata Wash Equipment - TATA Mining Truck Wheel Wash System

CONTACT US TO KNOW MOREIn two-wheel revolutions, the targeted spray configuration effectively cleans the tyre through 11 strategically placed delivery pipes. Fixed positioning of nozzles minimises striping and the spray pattern combined with galvanised high side screens retain water in the system.

The TWE Tyre Wash System is a compact high pressure spray wash system that operates automatically. Like all systems in the TATA WASHEQUIPMENT, it provides unrivalled reliability andperformance. The closed loop system also effectively recycles the water it uses.

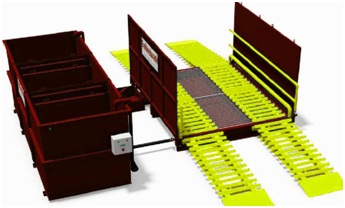

The TATA WASH EQUIPMENT TWE Tyre Wash comprises a robust 4m wash platform, optional 3m ramps and a water recycling tank totaling 22,000 litre capacity, all made from heavy duty steel. It is supplied with quality submersible pumps and the controls are housed in a IP65 rated cabinet.

The newly-improved wash platform benefits from 10 strategically positioned water delivery pipes that spray narrowfans of water up to three bar pressure to a targeted location on each tyre. The staggered positioning of the nozzles ensures the whole tyre is cleaned without the occurrence of striping. Manual shut off valves are fitted to provide a personalized spray configuration, if desired. The standard spray pattern is configured to minimize overspray and high side screens come as standard to ensure any deflected wateris directed back into the wash platform. The wash operates on a timer that can be adjusted to suit the changing needs of site.

A unique compact side sump, removable grids and improved wash down pipework make it the easiest system available to clean and maintain. Guide rails are supplied in sections for easy replacement in the unlikely event of damage.

The water recycling tank is divided into three sections by baffle and weir plates to aid particulate settlement and water quality. Sludge removal is easily performed either by opening the drain plug at the base of each chamber or via mechanical bucket from above. A clean head of water is located in the final chamber which ensures there is always sufficient clean water for use on demand. A mechanical ball valve enables automatic top-up from a mains water supply, when required.