TATA

WATER RECYCLING

PLANT

HomeTata Water Recycling Plant

Tata Wash Equipment - Water Recycling Plant

CONTACT US TO KNOW MORE

Equipment Work Principles

Water is not only essential for life but equally important for the industries & service centers as it is being one of the most critical elements.

A water recycling system not only helps to save water but is one of a step for the business to become sustainable in the world of competition.

We at Tata Wash Equipment, think of giving our customers along with our Vehicle Wash System, a water recycling plant as a package to help our customers save water.

Water is not only essential for life but equally important for the industries & service centers as it is being one of the most critical elements.

A water recycling system not only helps to save water but is one of a step for the business to become sustainable in the world of competition.

We at Tata Wash Equipment, think of giving our customers along with our Vehicle Wash System, a water recycling plant as a package to help our customers save water.

With this plant we can serve you to:

Tata Wash Equipment have been developed into various modules which can be selected by the client as per their requirement providing flexibility to the client.

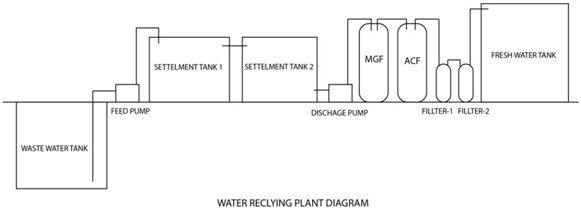

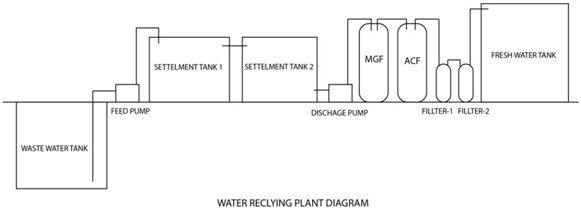

The various components of the system are as follows the inflow water may contain trash like plastic piece, thermo coal, cardboard, etc. which needs to be trapped before entering the recycling unit which otherwise can damage the equipment. The car washing system would involve oil and grease to flow into the system which needs to be taken care of. A specially made RCC chamber retains waste water and allows oil to float at the top layer. This layer can be skimmed off time to time making water free from oil & grease.

The water from the Oil and Grease Trap then enters the collection tank where chemical is dozed in measured quantity to react with the other impurities and make it settle at the bottom. The other impurities may start coagulating and start floating which can be removed further.

This is a small but efficient metering pump to dose measured quantity of coagulant chemical. Coagulant increases the efficiency of settler to separate water and sludge. A settler is a prefabricated tank used to separate sludge. The water from collection tank is transferred into settler through a pump. Here the suspended dust and other fine particles would get settled at the bottom in the tank. The clarified water can be transferred to another tank. The clarified water is pumped to pass through MGF which would further remove suspended solids and turbidity from the water. The filtered water then enters ACF where the remaining of odour and colour is effectively absorbed by Activated carbon making water look crystal clear.

Step 2: The water from collection tank is transferred into settler through a pump. Here the suspended dust and other fine particles would get settled at the bottom in the tank. The clarified water can be transferred to another tank.

Step 3: The step 3 consists of Multimedia filtration which removes the fine dirt from the water. The water is charged into the vessel with a combination Sand, Gravel and Anthracite.

Step 4: The water is passed through Activated Carbon filter which increases the filtration level along with removing bad odour from the water. The Activated carbon works on the Adsorption principle rather than absorption which makes it more effective.

Features: - High Rate of Filtration High Filtrate Quality

- Lower Frequency of Backwash Low Pressure Drop

- High Dirt Holding Capacity

Working Principle

The working principle of a multi grade filter is quite straight forward. In a multi grade filter or pressure sand filter, water is passed through multi layers of filter media consisting graded sand, pebbles and gravels layers. The contaminants in the water are captured in the media bed and filtered water passes into the discharge manifold at the bottom of the tanks. The next and last step is backwashing, a process of effectively removal of captured contaminants from the media bed. After back-washing the filter is rinsed with raw water and after the required quality of water is achieved the filter is put back intoservice.

Activated Carbon Filters

Carbon bed media filters are utilized as polishers for residual organics and chlorine removal. Various options are available for the carbon media form the normal Iodine value to higher Iodine value carbon for specialized applications. Activated Carbon Filter Working Principle An activated carbon filter (ACF) works on the principle of adsorption; filter medium adsorbs or reacts with a pollutant molecules then filtered water is drained out. Activated carbon which is used as medium to remove contaminants is natural material derived from coconut shell, lignite, bituminous coal etc. further, activated by chemical or steam under absence of oxygen with high temperature around 1000°C. Specific contaminants can be removed by employing blends of various carbons.

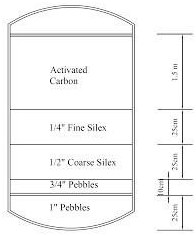

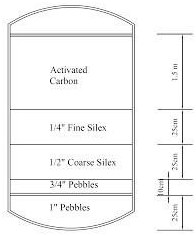

ACF VESSEL DETAIL

ACF VESSEL DETAIL

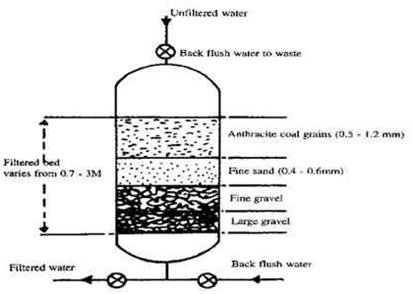

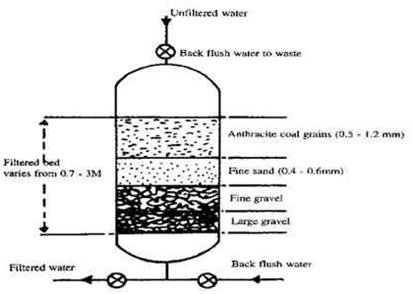

MGF VESSEL DETAIL

MGF VESSEL DETAIL

- Reduce your cost of operation by reusing water.

- Provide Clients with an Eco-Friendly solution.

- Overcoming water scarcity situations.

- Adhering to environmental issues.

- Easy to operate - A one stop solution.

Tata Wash Equipment have been developed into various modules which can be selected by the client as per their requirement providing flexibility to the client.

Working Procedure

The waste water generated during vehicle washing is processed through the various levels which either can be pumped from a collection tank/sump or through gravity can be fed into the recycle systems.The various components of the system are as follows the inflow water may contain trash like plastic piece, thermo coal, cardboard, etc. which needs to be trapped before entering the recycling unit which otherwise can damage the equipment. The car washing system would involve oil and grease to flow into the system which needs to be taken care of. A specially made RCC chamber retains waste water and allows oil to float at the top layer. This layer can be skimmed off time to time making water free from oil & grease.

The water from the Oil and Grease Trap then enters the collection tank where chemical is dozed in measured quantity to react with the other impurities and make it settle at the bottom. The other impurities may start coagulating and start floating which can be removed further.

This is a small but efficient metering pump to dose measured quantity of coagulant chemical. Coagulant increases the efficiency of settler to separate water and sludge. A settler is a prefabricated tank used to separate sludge. The water from collection tank is transferred into settler through a pump. Here the suspended dust and other fine particles would get settled at the bottom in the tank. The clarified water can be transferred to another tank. The clarified water is pumped to pass through MGF which would further remove suspended solids and turbidity from the water. The filtered water then enters ACF where the remaining of odour and colour is effectively absorbed by Activated carbon making water look crystal clear.

Steps in Water Recycling

Step 1: Sludge and water from the wash water. This happens above the ground level and you need not create multiple settling tanks to remove the oil and sludge. Also all the maintenance to be done is all above ground without even stopping the washing process.Step 2: The water from collection tank is transferred into settler through a pump. Here the suspended dust and other fine particles would get settled at the bottom in the tank. The clarified water can be transferred to another tank.

Step 3: The step 3 consists of Multimedia filtration which removes the fine dirt from the water. The water is charged into the vessel with a combination Sand, Gravel and Anthracite.

Step 4: The water is passed through Activated Carbon filter which increases the filtration level along with removing bad odour from the water. The Activated carbon works on the Adsorption principle rather than absorption which makes it more effective.

Equipment capacity - 2000 liters / hour (8.8 gpm)

MGF & ACF details and drawings

Multi-grade filters This type of filter utilizes a dual grade of sieved and graded sand based media with graded silex and pebbles as support media. Fabrication options are available for the external vessel either in mild steel or FRP. All filters come with custom designed internals to ensure even distribution of incoming water, uniform collection of the filtered water and proper dirt removal during backwashing.Features: - High Rate of Filtration High Filtrate Quality

- Lower Frequency of Backwash Low Pressure Drop

- High Dirt Holding Capacity

Working Principle

The working principle of a multi grade filter is quite straight forward. In a multi grade filter or pressure sand filter, water is passed through multi layers of filter media consisting graded sand, pebbles and gravels layers. The contaminants in the water are captured in the media bed and filtered water passes into the discharge manifold at the bottom of the tanks. The next and last step is backwashing, a process of effectively removal of captured contaminants from the media bed. After back-washing the filter is rinsed with raw water and after the required quality of water is achieved the filter is put back intoservice.

Activated Carbon Filters

Carbon bed media filters are utilized as polishers for residual organics and chlorine removal. Various options are available for the carbon media form the normal Iodine value to higher Iodine value carbon for specialized applications. Activated Carbon Filter Working Principle An activated carbon filter (ACF) works on the principle of adsorption; filter medium adsorbs or reacts with a pollutant molecules then filtered water is drained out. Activated carbon which is used as medium to remove contaminants is natural material derived from coconut shell, lignite, bituminous coal etc. further, activated by chemical or steam under absence of oxygen with high temperature around 1000°C. Specific contaminants can be removed by employing blends of various carbons.

ACF VESSEL DETAIL

ACF VESSEL DETAIL

MGF VESSEL DETAIL

MGF VESSEL DETAIL